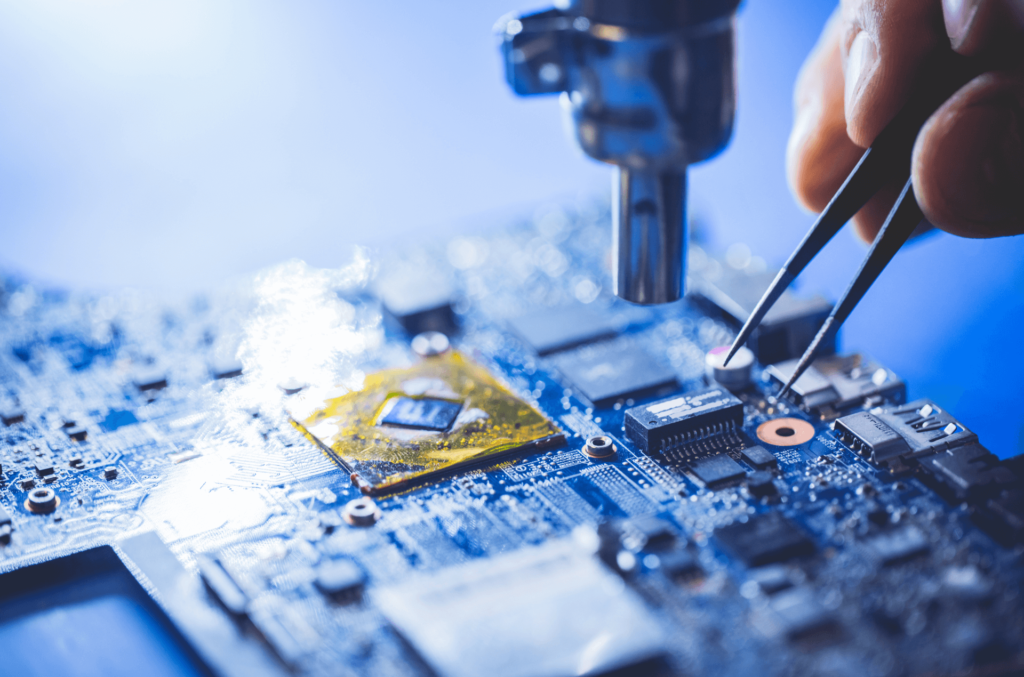

From routine maintenance to advanced software updates, we provide top-notch services to keep your CNC machines and hardware running at peak performance.

Looking for reliable CNC maintenance, software updates, training, or hardware installation?